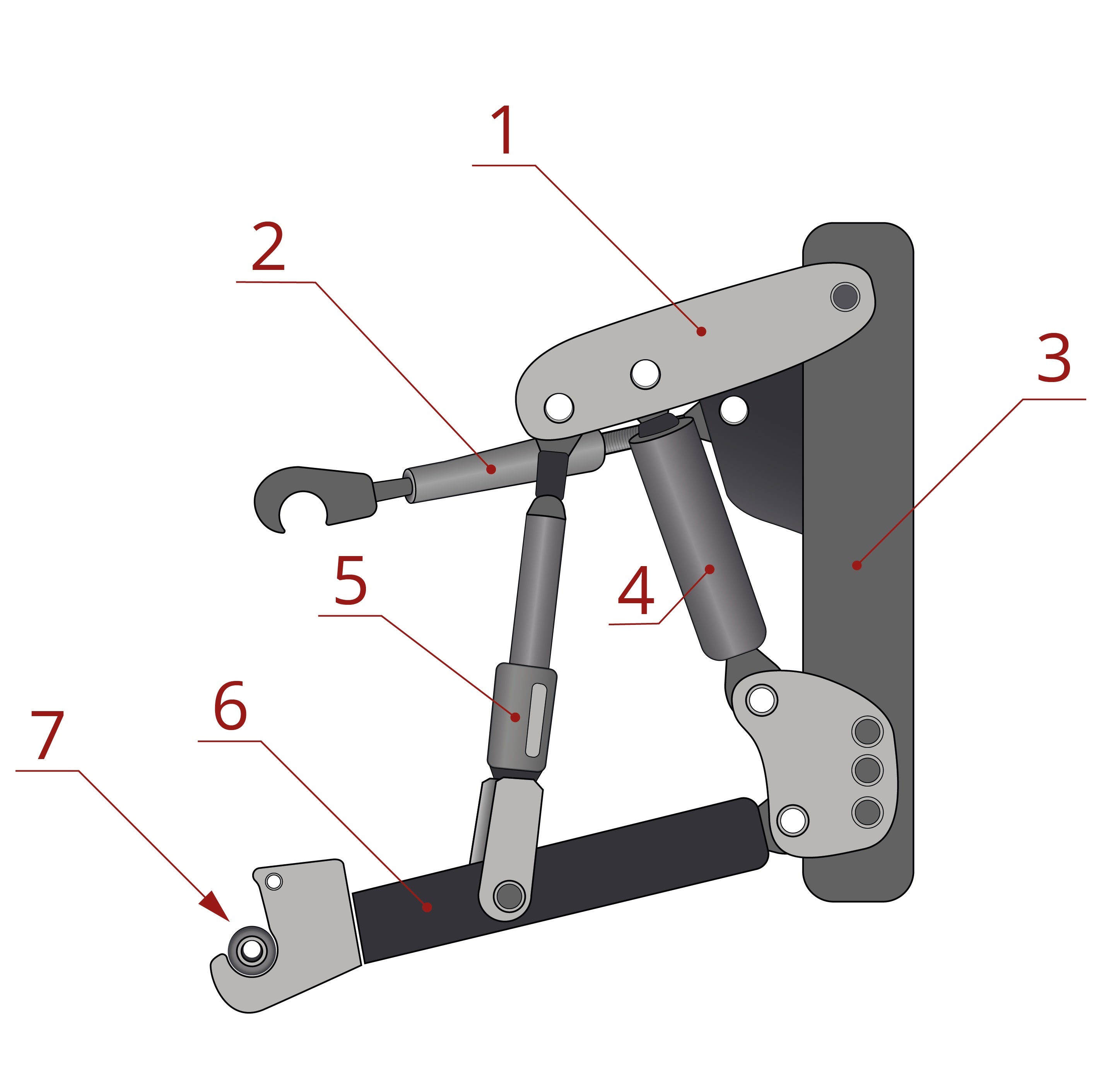

Linkage and coupling parts are the components that connect your tractor to your implement. The top link and the two lower link arms, which together make up the three-point linkage, form the only connection between the two vehicles. This serves as the basis for the lifting mechanism. The linkage can be mounted either at the front or the rear. The top link is adjustable in length and supports the weight of the implement when it is raised or lowered.

There are a number of aspects to consider when choosing the linkage and coupling parts that are right for you. These are:

- Implement hitch category

- Power take-off (ISO 730)

- Dimensions

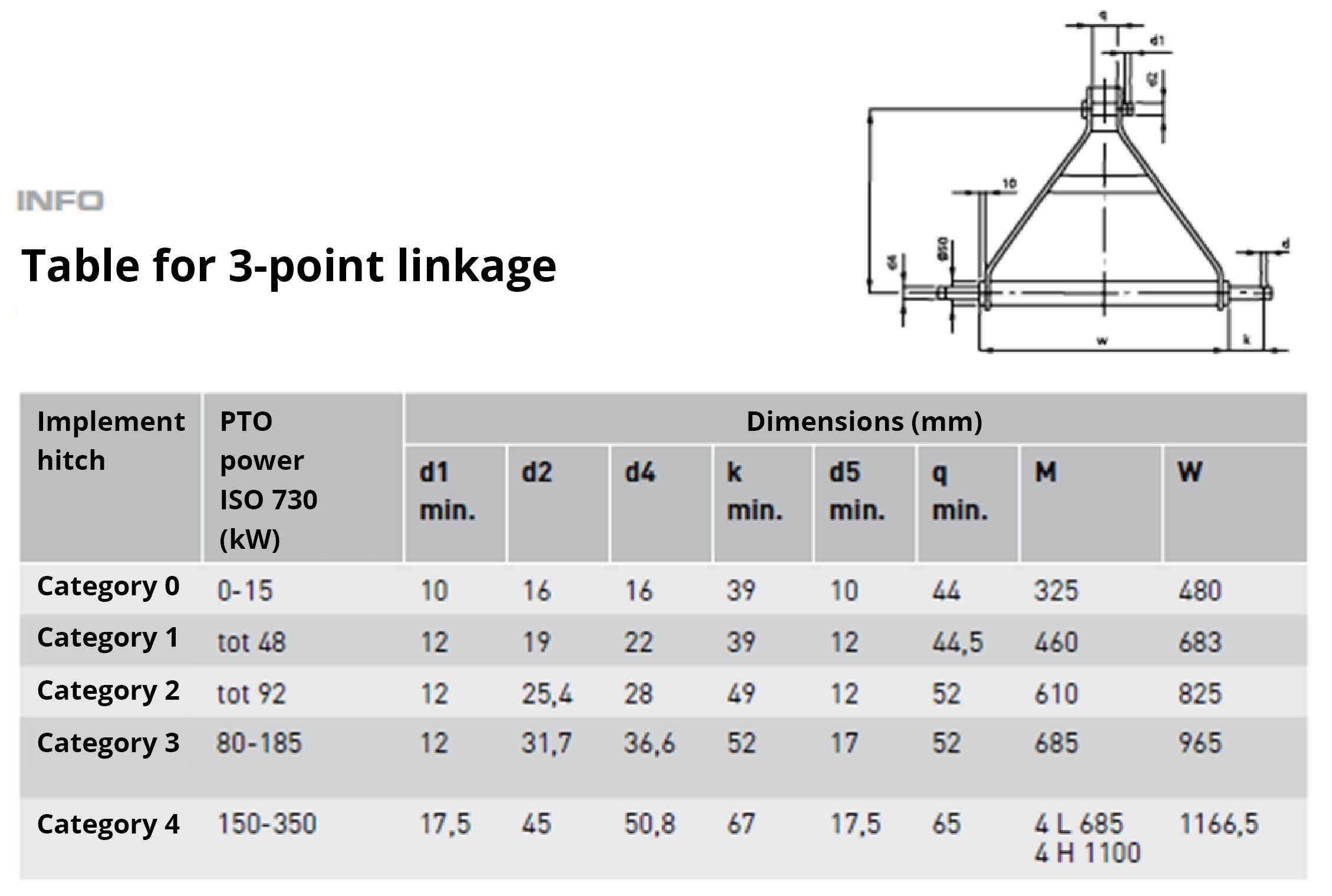

Implement hitch category

There are five three-point hitch size categories. Which one suits your purposes depends on the power of your tractor. The higher the category, the sturdier the link arms and top link, and the thicker the pins. This allows them to withstand greater force.

Power take-off (ISO 730)

The three-point linkage (i.e. the top link mechanism) is designed to attach different types of implements or equipment to a tractor. The ISO 730 standard sets out the standard sizing and bolt strength.

Dimensions

The table and chart below can help you make the right choice in terms of linkage and coupling parts.

Table for 3-point linkage

Table for 3-point linkageOlder-models tractors typically have ball joints. More recent models come with link hooks that have to be used in combination with the right lower link and top link balls. The outside diameter of the link ball is determined by the category size of the link hook. The opening in the link ball should fit the pin diameter of the attachable implement.

Materials, quality and coating

As a tractor operator, you want these key components to be made of high-quality materials. You can rely on premium brands and our Kramp private labels to offer you the best quality. The parts are manufactured from excellent raw materials that have been handled expertly, they have been treated using a top-class hardening process and they have been finished to perfection. Items from the Kramp Black Line range are extremely suitable for heavy and intensive use, as well as featuring a special Electrophoretic Deposition (ED) coating. This means that they have been subjected to an electrostatic process with both positively and negatively charged parts. In this coating process, the parts are immersed in a water bath. Using electricity, the positively charged paint particles attach themselves to the metal surface, providing excellent adhesion and a highly scratch-resistant coating that offers maximum protection against corrosion. ED coating provides no less than seven times more protection than traditional galvanisation.

1 = lifting arm

2 = top link

3 = tractor mount

4 = lifting cylinder

5 = lift link

6 = lower link arm

7 = link ball

1 = lifting arm

2 = top link

3 = tractor mount

4 = lifting cylinder

5 = lift link

6 = lower link arm

7 = link ballPlease do not hesitate to reach out to a Kramp product specialist to find out more about linkage and coupling parts. Alternatively, you can contact a Kramp dealer near you or send us an email at knowledgecenter@kramp.com.