In the evolving world of abrasive technology, 3M™ introduces a groundbreaking advancement with Cubitron™ 3. This new line has been introduced to address the common challenges of rapid tool wear and high operational costs in grinding and cutting tasks. Featuring 3M™’s proprietary Precision-Shaped Grain technology, Cubitron™ 3 sets new performance standards, increases product lifespan, and contributes to sustainable management.

Why Choose Cubitron™ 3?

Cubitron™ 3 sets a new industry standard in abrasive performance by offering significant improvements over its predecessor, Cubitron™ II. With redesigned ceramic triangular grains, this latest iteration not only improves cut rate but also extends the operational life of each tool to up to three times. This means fewer replacements, reduced downtime, and overall cost savings—crucial benefits in today’s high-demand workshops.

Advancements from Cubitron™ II

Cubitron™ II was introduced as the first abrasive with precision-shaped crushed ceramic grain, offering substantial improvements over traditional aluminum zirconia abrasives.

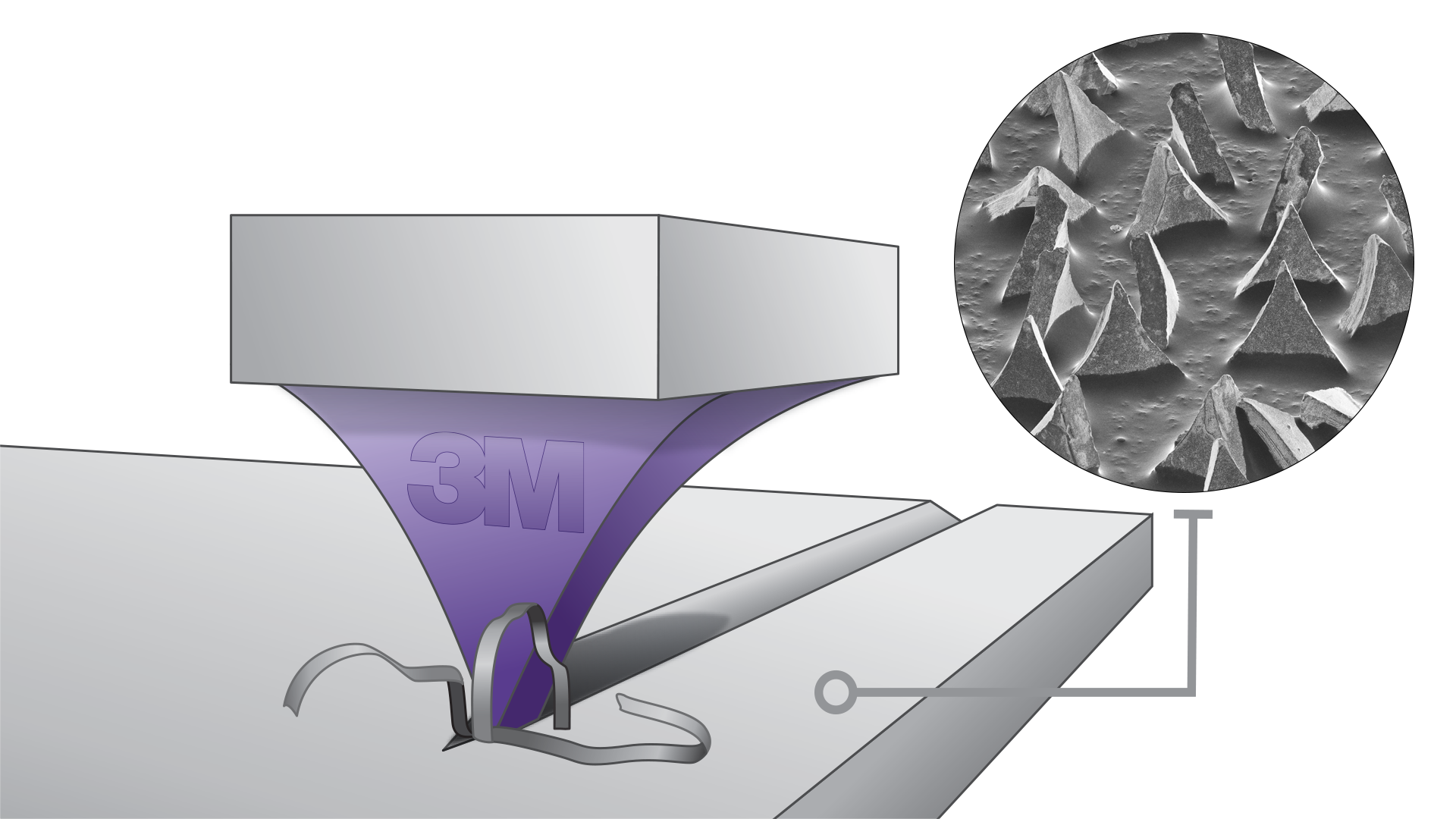

The Cubitron™ II mineral with precision-shaped crushed ceramic grain.

The Cubitron™ II mineral with precision-shaped crushed ceramic grain. Building on this innovative foundation, Cubitron™ 3 further refines the grain shape and bonding technology, ensuring even greater durability, speed, and consistency in finish.

The Cubitron™ 3 mineral has been reformed with unique breakout properties and placement on the carrier.

The Cubitron™ 3 mineral has been reformed with unique breakout properties and placement on the carrier.Key Benefits of Cubitron™ 3

- Higher Productivity: The superior cutting performance and longevity of Cubitron™ 3 allow for faster completion of tasks and less frequent tool changes, boosting workshop throughput.

- Cost Efficiency: Extended tool life translates into lower overall costs by reducing both direct expenses (like the need for new abrasives) and indirect costs (such as labor and machine downtime).

- Safety and Sustainability: Cubitron™ 3 aligns with modern safety standards, mitigating risks like respiratory, vibration, and noise hazards. Its durability also supports sustainable practices by reducing waste and environmental impact.

Explore The Range of Cubitron™ 3 Abrasives

Cubitron™ 3 products, including grinding wheels, cut-off wheels, and fiber discs, are available at the Kramp webshop. Remember to always wear appropriate Personal Protective Equipment (PPE) when handling abrasive tasks to ensure safety and compliance with industry standards.

3M™ Cubitron™ 3 Sparks a New Era of Performance: Produce more. With less.

Fibre Discs

Elevate productivity in medium to heavy-duty operations. 3M discs offer superior durability and longer life, with higher cut rates and less grinding pressure. See the upgrades from Cubitron™ II in the video and learn more about fibre discs in the dedicated brochure.

Feel the Power! Watch 3M™ Cubitron™ 3 Fibre Discs Conquer Four Heavy Grinding Applications LIVE!

Cut-Off Wheels

Ideal for precise, clean cuts through various metals. Use these wheels for projects involving autobody or marine sheet metal, stainless steel tubing, and more.

Depressed Center Grinding Wheels

These wheels are perfect for heavy-duty grinding tasks, such as weld removal. They're specially formulated to work on stainless steel, mild steel, and aerospace alloys.

Cut and Grind Wheels

These versatile wheels combine cutting and grinding capabilities, allowing for cutting, grinding, gouging, and more. This dual-purpose tool simplifies your toolkit while maximizing productivity.

Learn more about cut-off wheels, depressed center grinding wheels and cut and grind weels in the brochure.

The Cubitron™ 3 portable bonded wheels family.

The Cubitron™ 3 portable bonded wheels family.Meeting Industry Challenges

The development of Cubitron™ 3 is a proactive response to several pressing industry trends, including an aging workforce, increasing safety standards, automation, economic pressures, and a focus on sustainability. By addressing these challenges, Cubitron 3 ensures that your operations are not only current but also future-proof, ready to meet the demands of both routine and complex tasks with the highest possible efficiency.

You want to learn more about 3M solutions for Metal Working in general? Check out the process guides about cutting, grinding & cleaning as well as the brochure about finishing processes.

Share This Article With Your Customers!

Spread this article among your customers through your website, newsletters, social media platforms, or other communication channels you use. Together, we can enhance the overall customer experience and showcase the value of our products and services.

Questions?

Our team is ready to support you in providing advice to your customers. If you have questions or need more information, don't hesitate to contact our product specialist or send an email to the knowledge center. If you are a private customer looking for the products mentioned in this article, find a Kramp dealer near you.