How often should PTO driveshafts be serviced and why is servicing so important?

The power take-off driveshaft (a.k.a. power take-off or PTO driveshaft) uses the mechanical power of the tractor and transmits it to the drive of the attached machine. And it is this enormous power that hides a danger that some users may unfortunately begin to underestimate. Serious accidents related to PTO driveshafts, sometimes even fatal, still occur every year in Europe, mainly as a result of entanglement. Other accidents occur when the PTO driveshaft disengages while the machine is running, hitting a farmer, farm worker or even a family member. A regularly and properly serviced PTO is much safer to operate. Together with a PTO driveshaft expert from the company Walterscheid we will tell you about service and maintenance to ensure safety.

However, before we say more about servicing and maintaining the PTO driveshaft, we would like to point out the invaluable importance of the PTO driveshaft guard, also known as the PTO guard. The guard and protective caps cover almost the entire driveshaft, and slip rings fitted inside the guard allow the driveshaft to rotate at a particular speed while the guard remains stationary. This is to prevent clothing, shoelaces or other objects from snagging on the roller and any person from becoming entangled. An entangled coat or shoelace can result in serious injury or death, as there is no time to react in such a situation. Check the PTO driveshaft guards after each use. If they are dented or distorted, become loose or start to rotate with the driveshaft, they must be repaired or replaced immediately.

How often should the PTO driveshaft be serviced?

You may have already read our article on how to extend the service life of your PTO driveshaft. The main lubrication tip demonstrates why there is so much confusion around the maintenance and servicing of the PTO driveshaft: depending on the manufacturer, the model of the driveshaft and its application, it can require fresh lubrication as often as every eight hours of operation or as little as every 250 hours! That’s quite a long time...

Fortunately, after a five-year programme involving extensive laboratory and field testing, Walterscheid, a PTO driveshaft manufacturer, has developed a new system for determining the correct intervals between PTO driveshaft inspections. The company calls it the ServicePlus system, and its introduction has been made possible by improving a whole range of Walterscheid PTO driveshaft components, from cross welds to profile tubes. As a result, maintenance expenditure can be reduced by up to 70% for some PTO driveshafts.

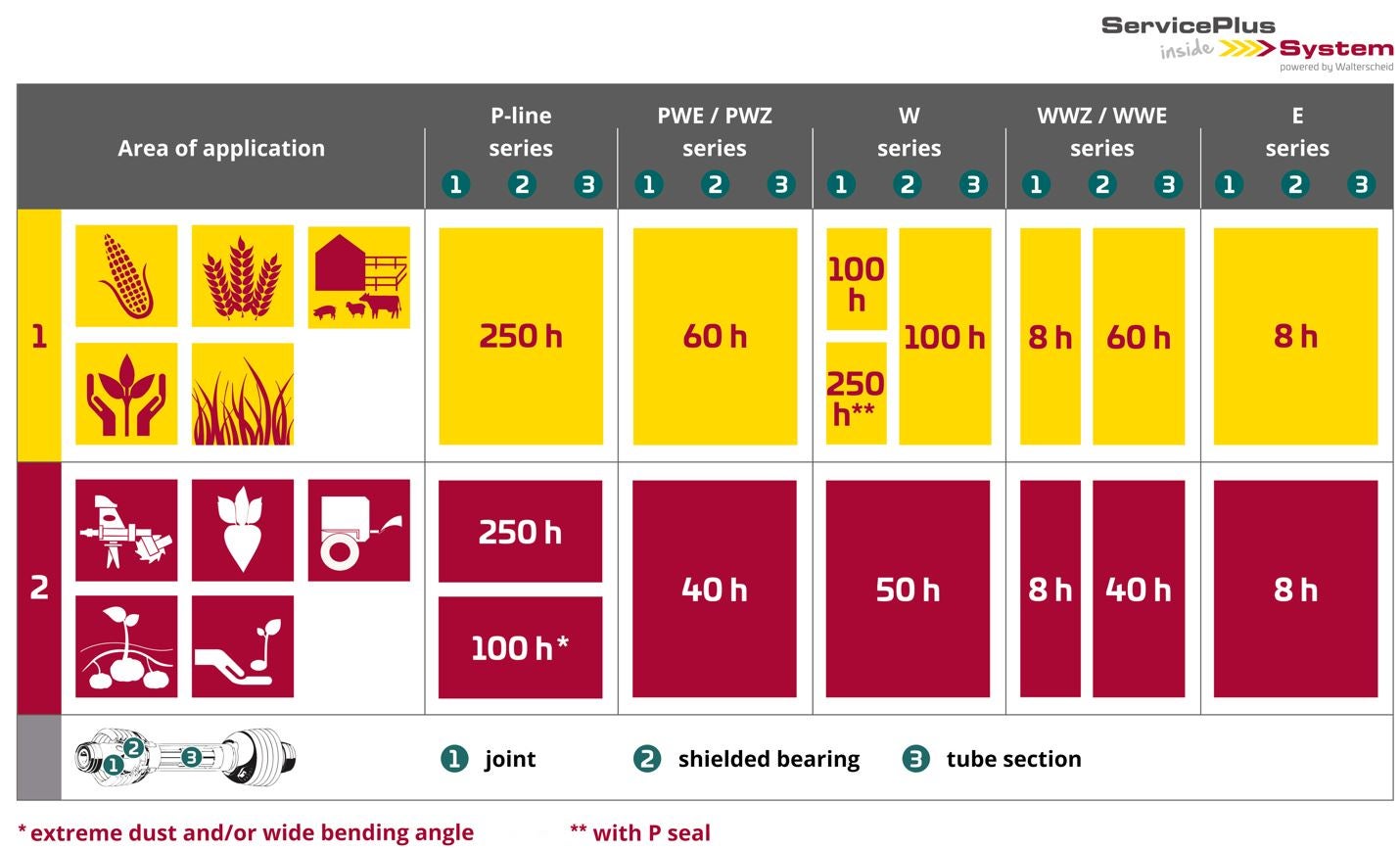

The new system divides maintenance intervals into hours, depending on the individual models in the range and on-site applications. This is summarised in a table which can be seen here. For example, the W-series driveshaft’s joints can be serviced every 100 hours of operation when the driveshaft is used for maize harvesting and every 250 hours when fitted with the company’s P-type seal. On the other hand, if the W-series driveshaft is used exclusively for digging up the potatoes, then the joints – and the rest of the driveshaft – will need inspection every 50 hours of operation. Please note that joints, shield bearings and profile tubes may need to be inspected and lubricated at different intervals, depending on the model and use.

The benefits include a less frequent need for the farmer to carry out maintenance ‘just in case’ and a much lower risk of damage to the shaft itself, surrounding machinery and, of course, workers. An additional advantage is that this system is more environmentally friendly, as less grease is used. Walterscheid also uses a high-performance lubricant (Shell Retinax GL-2) for all jointed driveshafts, an important factor in achieving the predictability of the new system.

Application-specific maintenance

The ServicePlus system can, of course, be used for Walterscheid products only. As always, farmers using PTO driveshafts from other manufacturers will have to rely on the guidelines received when purchasing parts.

The peace of mind and financial savings from reduced downtime are only possible because Walterscheid has tested each PTO driveshaft model – distinguishing between wide-angle and standard driveshafts – for each practical application to determine the length of safe maintenance intervals. Less intensive uses, such as grass cutting or maize harvesting, have the W1 maintenance class, while more strenuous work, such as soil cultivation, falls into the W2 maintenance class.

We recommend that farmers and machine operators print out the table and keep it where they store the PTO driveshafts when they are not in use. Recording hourly consumption, day by day, on a chart kept in the same place will make the servicing of this most important appliance easier.

The range of Walterscheid PTO driveshafts can be found in the Kramp online shop, and this article on how to choose the right PTO driveshaft will make the purchasing process easier for you. And don’t forget that when it comes to questions about agricultural equipment from all our suppliers, there is no better source of advice than your Kramp customer adviser.